What are fiber lasers?

Fiber laser are often referred to as Marking laser used. They mark and engrave various materials. They can also be used as cutting lasers for metals. Precise and permanent laser markings make this type of laser popular in many industries.

Fiber laser function and structure explained

How a fiber laser produces radiation

Fiber laser with a wavelength of 1064 nanometers (nm) use a special glass fiber.

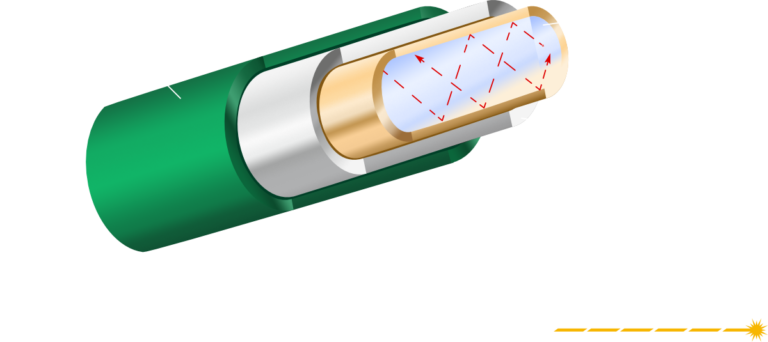

This glass fiber has three layers: the core, the sheath and the cladding.

The core is the inside of the glass fiber in which the light is transported. The cladding is a layer around the core.

It helps to keep the light in the core. It also guides the light along the glass fiber.

This coating protects the glass fiber. It ensures that the glass fiber remains flexible and bendable to a certain degree.

Inside the nucleus are tiny particles called ytterbium (doping).

When light is passed through the fiber, these ytterbium particles are excited.

The excited ytterbium particles release light particles. These light particles jump through the nucleus and meet other excited ytterbium particles. The resulting chain reaction produces more and more energy in the form of light.

Finally, this amplified light is let out through one side of the fiber. The light that is produced is invisible as it is in the infrared range.

This type of laser is used in many areas. For example, it is used in industry for cutting metals.

MOPA vs. Q-Switched fiber laser: Differences

MOPA- and Q-switched are two types of fiber lasers. They use different methods to generate the laser beam. MOPA systems are often the better choice due to their more precise control options.

Advantages of MOPA fiber lasers

With MOPA systems, the laser light is generated slowly and in a controlled manner. It is then amplified. This is similar to slowly turning on a tap and then letting the water flow more strongly. This enables precise control of the pulse energy and pulse duration.

This flexibility makes MOPA lasers ideal for applications that require precise control of the light output. - This includes the laser marking of products.

MOPA lasers offer a large possible range for controlling the frequency and also an adjustable pulse width. This enables them to produce excellent annealing markings. They can also be used to laser mark many plastics.

Q-Switched lasers compared to MOPA lasers

Q-Switched lasers generate very fast and powerful laser pulses. These short, strong pulses are good for applications that require high power. One example is the deep engraving of metals.

Q-switched fiber lasers offer less flexibility. They have limited control of the pulse energy and pulse duration. This is in comparison to MOPA lasers. The pulse width is fixed and not adjustable and the frequency range is rather small compared to a MOPA device.

MOPA fiber laser or Q-Switched: This is the one you should buy

In summary, MOPA fiber lasers offer precise control and better repeatability of light parameters. Q-switched lasers are good for high peak power applications. However, they offer less flexibility in control.

Ultimately, the choice between the two systems depends on the specific requirements of the application. As a rule, however, a MOPA variant is the better choice for most users.

Fiber lasers: Areas of use and applications

Laser marking on metals and plastics

Fiber lasers are used in industry for laser marking on metals, plastics, ceramics, glass and other materials. They can apply logos, serial numbers, barcodes, QR codes, text and other information precisely and permanently.

Component marking using fiber lasers in the automotive industry

In the automotive industry, fiber lasers are used for laser marking or laser engraving of spare parts, components and tools. These can be engine blocks, transmission components, valves or plastic parts, for example. The laser markings are used for traceability, identification and quality assurance.

Product labeling in the electronics industry

Fiber lasers are used for laser marking of electronic components, circuit boards and microchips. They can apply tiny codes, serial numbers or specific information without damaging the sensitive components.

Laser marking of medical devices and instruments

Fiber lasers are used in medical technology for laser marking of surgical instruments, medical devices, implants or packaging. The precise markings enable clear identification, traceability and sterilization.

Fiber lasers in the jewelry, watch and advertising materials industry

Fiber lasers are used for individual laser engraving of jewelry, watches, precious metals and gemstones. They can apply fine details, patterns and personalized information.

Packaging industry

Fiber lasers enable the laser marking of packaging, labels and film materials. For example, they can apply manufacturer information, expiry dates, batch codes or logos.

Food and beverage industry

Fiber lasers are used for marking food and beverages, especially glass bottles, cans and packaging. They can precisely apply barcodes, product information, serial numbers or quality markings.

The areas of application for fiber lasers for laser marking and laser engraving are diverse and extend across various industries. The precise and permanent markings enable improved traceability, identification, quality control and branding of products and components.

Which materials can a fiber laser engrave

Fiber lasers are versatile and can process a wide range of materials for different applications.

Fiber lasers can engrave, deep engrave, temper and decoat (e.g. powder-coated or painted components).

Here are some examples of materials that can be processed with a fiber laser:

Labeling metals and plastics

- Metals: steel, stainless steel, aluminum, copper, brass, titanium

- Plastics: acrylic, ABS, PET, PETG, PC, PMMA and many more. (with adjustable pulse width)

- Ceramics

Deep engraving of metals

- Metals: steel, stainless steel, aluminum, copper, brass

- Other hard metals

- Ceramics

- Hard plastics

Annealing markings on metals with MOPA technology

- Stainless steel

- Anodized aluminum

- Titanium

- Brass

Decoating of coated surfaces with a fiber laser

- Color coatings: Paints, varnishes, powder coatings

- Oxidation layers: Anodized layers on metals

- Protective coatings: Protective coatings, plastic coatings

- Conductor tracks: Electronic tracks on printed circuit boards

- Thermally conductive pastes: Thermal connections on electronic components

The processability depends on various factors. These include the power, the focusing optics, the laser parameters and the requirements of the application.

How much power does a fiber laser need?

When selecting a fiber laser for Laser engravings and laser marking of plastics and metals, various laser powers are available. The exact laser power you need depends on various factors. These include the material to be processed, the desired engraving depth and the production speed.

Fiber laser with low power (up to 20W)

Low-power fiber lasers are good for simple laser marking on plastics and thin metal coatings. These lasers are usually inexpensive. They are ideal for small production environments or for use in laboratories.

The engraving area should not exceed 110 x 110 mm.

Laser marker with medium power (up to 60W)

Fiber lasers with medium power are in the range of 30 to 60 watts. They offer a good mix of power and accuracy. They are good for engraving metals such as stainless steel, aluminum and brass. These lasers are generally versatile and are often used in industry.

A system with 60W can be considered a good all-rounder. Fiber lasers for commercial or industrial use should not be used with less than 30W. This allows you to react flexibly to changes.

Marking laser with high power (> 80W)

Fiber lasers in this performance class are able to perform deep and very fast engravings in metals. They offer a high production speed and are ideal for demanding applications in metal processing and industrial manufacturing.

Lasers with this power are also often used in the jewelry sector for cutting thin sheets up to 1 mm, e.g. for name chains.

It is important to know that the laser power depends on other factors. These include the beam diameter and the focusing of the laser. A wider beam diameter can be useful in some applications. However, a narrow, focused beam has a higher energy density.

When selecting the laser power, you should consider the requirements of your application. Think about the materials you want to process and your desired production rate. It is advisable to ask experts for advice. This will help you find the best laser power for your specific needs.

This is the service life of a fiber laser

The lifetime of lasers can vary greatly and is influenced by several factors, including the type of laser, the quality of components used, operating conditions and maintenance. Here are rough estimates for the lifetimes of fiber lasers, CO2 lasers (glass tube and metal tube) and UV lasers:

Comparison of the service life between fiber lasers, CO2 lasers and UV lasers

No Data Found

No Data Found

The service life of fiber lasers is generally very long, especially if they are properly maintained.

High-quality fiber lasers can often achieve a service life of up to > 80,000 operating hours.

However, factors such as cooling and the condition of the optical components can have a major impact on the service life.

Purchase recommendation for your marking laser

GRAVIS fiber laser for laser engraving of metals and plastics

The GRAVIS fiber laser as a safe laser solution for your business.

Thanks to the modern MOPA technology can be used with the Gravis produce precise, high-contrast or even colored laser markings and laser engravings on many materials.

Laser protection class 1 offers maximum safety for many areas of application.

Thanks to the movable X-axis, large marking fields can be realized as standard, ideal for series production.