What are fiber lasers?

Fiber laser are most frequently referred to as Marking laser used for laser marking and laser engraving of various materials, alternatively also as a cutting laser for metals. Precise and permanent laser markings make this type of laser popular in many branches of industry.

Fiber laser function and structure

We explain the structure of a fiber laser and how a fiber laser produces radiation

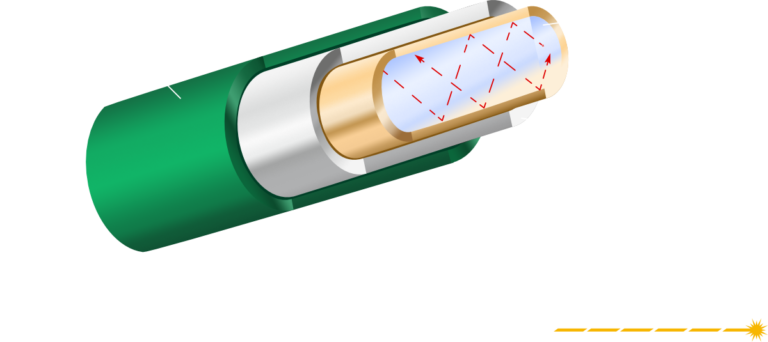

Fiber laser with a wavelength of 1064 nanometers (nm) work with a special glass fibre that consists of three layers: the core, the cladding and the coating. The core is the inside of the glass fiber in which the light is transported. The cladding is a layer around the core that helps to keep the light in the core and guide it along the glass fiber. This cladding protects the glass fiber and ensures that it remains flexible and, to a certain extent, bendable.

Inside the core are tiny particles called ytterbium (doping). When light is passed through the fiber, these ytterbium particles are excited.

The results stimulated by the Ytterbium Particles released light particles jump through the nucleus and encounter further excited ytterbium particles. The resulting chain reaction produces more and more energy in the form of light.

Finally, this amplified light is let out through one side of the fiber. The light that is produced is invisible as it is in the infrared range.

This type of laser is used in various areas, such as in industry for cutting or ablating metals.

MOPA fiber lasers or Q-Switched fiber lasers the differences

MOPA and Q-switched fiber lasers are two different types of fiber lasers that use different methods to generate the laser beam. MOPA systems are often the better choice due to their more precise control options.

Fiber laser as MOPA variant

With MOPA fiber lasers, the laser light is generated slowly and in a controlled manner and then amplified again, similar to slowly turning on a tap and then increasing the water flow. This enables precise control of the pulse energy and pulse duration. This flexibility makes MOPA lasers ideal for applications where precise control of light output is required, such as laser marking of products or material processing. MOPA systems also offer better reproducibility of laser parameters over long periods of use. MOPA fiber lasers excel with their wide frequency ranges and variable pulse widths, allowing them to produce excellent annealing markings and laser mark a wide variety of plastics.

Fiber laser as Q-Switched

Q-switched fiber lasers, on the other hand, generate very fast and strong light pulses, similar to a flash that briefly lights up and then disappears. These short, intense pulses are well suited for applications where high peak power is required, such as deep engraving of metals. However, Q-switched fiber lasers offer less flexibility in terms of pulse energy control and pulse duration compared to MOPA lasers. The pulse width is fixed and not adjustable and the frequency range is rather small compared to a MOPA device.

You should buy this fiber laser

In summary, MOPA fiber lasers offer precise control and better reproducibility of light parameters, while Q-switched fiber lasers are suitable for high peak power applications but offer less flexibility in control. Ultimately, the choice between the two systems depends on the specific requirements of the application. As a rule, however, a MOPA variant is the better choice for most users.

By loading the video, you accept YouTube's privacy policy.

Learn more

By loading the video, you accept YouTube's privacy policy.

Learn more

By loading the video, you accept YouTube's privacy policy.

Learn more

Fiber lasers - areas of use and applications

Where and for what are fiber lasers used?

- Fiber lasers for industrial laser marking

Fiber lasers are used in industry for laser marking on metals, plastics, ceramics, glass and other materials. They can apply logos, serial numbers, barcodes, QR codes, text and other information precisely and permanently. - Component marking using fiber lasers in the automotive industry

In the automotive industry, fiber lasers are used for laser marking or laser engraving of spare parts, components and tools. These can be engine blocks, transmission components, valves or plastic parts, for example. The laser markings are used for traceability, identification and quality assurance. - Product labeling in the electronics industry

Fiber lasers are used for laser marking of electronic components, circuit boards and microchips. They can apply tiny codes, serial numbers or specific information without damaging the sensitive components. - Marking of medical devices and instruments

Fiber lasers are used in medical technology for laser marking of surgical instruments, medical devices, implants or packaging. The precise markings enable clear identification, traceability and sterilization. - Fiber lasers in the jewelry and watch industry

Fiber lasers are used for individual laser engraving of jewelry, watches, precious metals and gemstones. They can apply fine details, patterns and personalized information. - Packaging industry

Fiber lasers enable the laser marking of packaging, labels and film materials. For example, they can apply manufacturer information, expiry dates, batch codes or logos. - Food and beverage industry

Fiber lasers are used for marking food and beverages, especially glass bottles, cans and packaging. They can precisely apply barcodes, product information, serial numbers or quality markings.

The areas of application for fiber lasers for laser marking and laser engraving are diverse and extend across various industries. The precise and permanent markings enable improved traceability, identification, quality control and branding of products and components.

Which materials can fiber lasers process

MOPA fiber lasers are versatile and can process a wide range of materials for different applications.

Fiber lasers can engrave, deep engrave, temper and decoat (e.g. powder-coated or painted components).

Here are some examples of materials that can be processed with a fiber laser:

Marking of metals and plastics using fiber lasers

- Metals: steel, stainless steel, aluminum, copper, brass, titanium

- Plastics: acrylic, ABS, PET, PETG, PC, PMMA and many more. (with adjustable pulse width)

- Ceramics

Deep engraving with fiber laser

- Metals: steel, stainless steel, aluminum, copper, brass

- Other hard metals

- Ceramics

- Hard plastics

Annealing marking with MOPA fiber lasers

- Stainless steel

- Anodized aluminum

- Titanium

- Brass

Decoating of coated surfaces with a fiber laser

- Color coatings: Paints, varnishes, powder coatings

- Oxidation layers: Anodized layers on metals

- Protective coatings: Protective coatings, plastic coatings

- Conductor tracks: Electronic tracks on printed circuit boards

- Thermally conductive pastes: Thermal connections on electronic components

The exact processability depends on various factors, including the power, the focusing optics, the laser parameters and the specific requirements of the application.

How much power/watt does a fiber laser need?

When selecting a fiber laser for Laser engravings and laser marking of plastics and metals, various laser powers are available. The exact laser power you need depends on various factors. These include the material to be processed, the desired engraving depth and the production speed.

-

- Fiber laser with low power (up to 20W)

Low-power fiber lasers in this power range are well suited for simple laser marking on plastics and thin metal coatings. These lasers are generally cost-effective and ideal for smaller production environments or for use in laboratories.

The engraving area should not exceed 110 x 110 mm. - Fiber laser with medium power (up to 60W)

Fiber lasers with medium power are in the range of 30 to 60 watts. They offer a good combination of power and precision and are suitable for engraving metals such as stainless steel, aluminum and brass. These lasers are generally versatile and are often used in industry. A system with 60W can be considered a good all-rounder. In general, you should not operate fiber lasers below 30W for commercial or industrial use in order to be able to react flexibly to changes. - Fiber laser with high power (> 80W)

Fiber lasers in this performance class are able to perform deep and very fast engravings in metals. They offer a high production speed and are ideal for demanding applications in metal processing and industrial manufacturing.

Lasers with this power are also often used in the jewelry sector for cutting thin sheets up to 1 mm, e.g. for name chains.

- Fiber laser with low power (up to 20W)

It is important to note that the exact laser power also depends on other factors, such as the beam diameter and the focusing of the laser. For example, a wider beam diameter can be advantageous for certain applications, while a more narrowly focused beam offers a higher energy density.

When selecting the laser power, you should consider the specific requirements of your application, the materials you want to process and your desired production rate. It is advisable to seek expert advice to determine the optimum laser power for your specific requirements.

Lifetime of a fiber laser

The lifetime of lasers can vary greatly and is influenced by several factors, including the type of laser, the quality of components used, operating conditions and maintenance. Here are rough estimates for the lifetimes of fiber lasers, CO2 lasers (glass tube and metal tube) and UV lasers:

No Data Found

The service life of fiber lasers is generally very long, especially if they are properly maintained. High-quality fiber lasers can often achieve a service life of up to > 80,000 operating hours. However, factors such as cooling and the condition of the optical components can greatly influence the service life.

Fiber lasers from the German

manufacturer

We will be happy to advise you free of charge!

+49 (0) 2952 67 99 745

Fiber laser Gravis

ALL-IN-ONE fiber laser for your company

GRAVIS marking lasers as a complete solution.

Thanks to the modern MOPA technology can be used with the Gravis produce precise, high-contrast or even colored laser markings, engravings or annealing colors.

Optionally available in Laser protection class 1 or 2, this marking laser offers a safe solution for many applications in your company.

Thanks to the optional X-axis, large marking fields can also be realized with small optics, ideal for series production or large components.

Fiber laser INTEGRA

Stand-alone laser marker as an integration laser

INTEGRA MK2 as a stand-alone or integration solution.

Various inputs and outputs can be freely programmed using the integrated PLC control.

Ideal if the laser marker is to be used in an existing process chain, e.g. in conjunction with robotics.

Thanks to the existing interlock connections, this marking laser can not only be easily but also safely integrated into laser safety rooms or enclosures.